Full Details

-

Ink Type Liquid Ink

-

IP Standartı IP54

-

CE Certificate Available

-

RoHS Available

-

Display dimensions 5.7" Colored LCD Touch panel

-

Umbilical Lengt 3,5 m

-

Nozzle Diameter 40/50/60 microns

-

Printing Height 0.8 mm - 5 mm 40 microns Nozzle - 1 mm - 10 mm 50 microns Nozzle - 2 mm - 10 mm 60 microns Nozzle

-

Maximum Printing Speed 5x5 font/sn 3200 40 micron Nozzle - 2449 50 micron Nozzle - 2136 60 micron Nozzle

-

Line Number and Fonts 【1 - 6 Satır】 5×5 【1 - 4 Lines】 7×5, 7×8 【1 - 3 Lines】 9×7, 9×9, 10×8, 12×10 【1 - 2 Lines】 16×12, 16×16 【1 Lines】 24×18, 24×24, 32×24, 32×32

-

Message Memory Maximum 999

-

Character Number in a Message Maximum 4096

-

Font Characters Symbols, Figures, Japanese, Chinese, Arabic, Cyrillic and Latin Alphabet

-

Time and Date Day, Month, Year, AM/PM Time, Week Number, Day of Week

-

Barcode ITF، NW7، JAN، Code39، Code128 DataMatrix، QR Code

-

Connections I/O, Signal Lamb Output, RS-232C, LAN, Printr, UPS, UBS Memory

-

Data Input Touch Screen, RS-232C Connection, Ethernet

-

Communication RS-232C 1CH Max.115, 200bps Ethernet

-

Environmental Conditions 0-40 degrees and 10%-85% Humidity

-

Power Source AC100 ~240V 80W

-

Weight 25 Kg

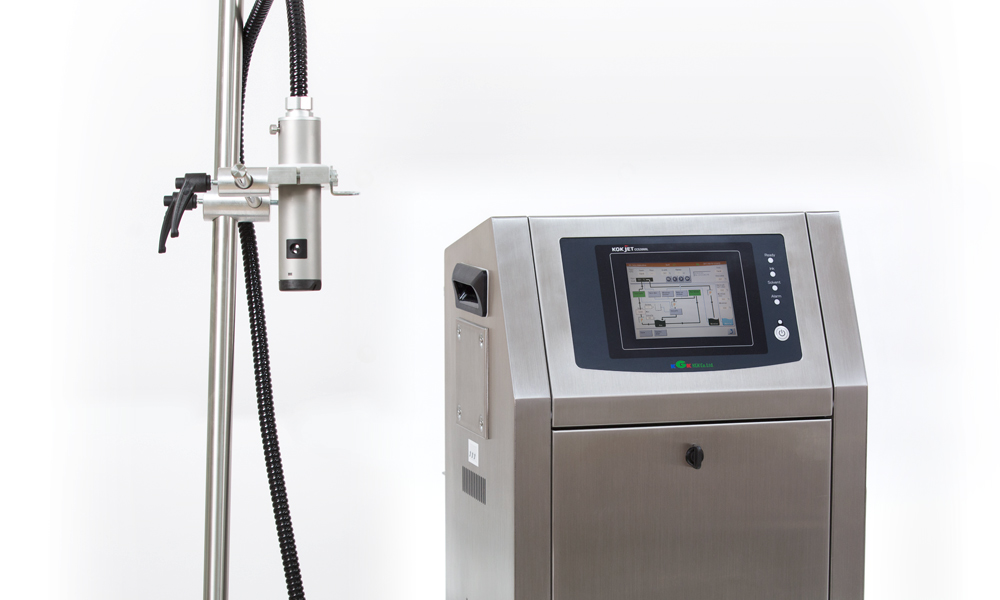

CCS 3000L Inkjet Printers

Manufactured in Japan, CCS 3000L inkjet printers have built a continuously growing global customer base with a high level of satisfaction. This success is driven by well-known features such as extremely low consumable usage, highly reliable electronic and mechanical components, and a long operational and economic lifespan.

CCS 3000L Powered by Advanced Japanese Technology

The CCS 3000L small character inkjet printer, developed in accordance with international standards, is designed to deliver maximum uptime and stable performance. Thanks to advanced Japanese technology and the proprietary CLOWP operating software, system interruptions are kept to a minimum.

CCS 3000L ensures high productivity with minimal issues in fast and demanding production environments. Designed for 24/7 continuous operation, it is an ideal solution for high-speed production lines.

Minimal Consumable Consumption

CCS 3000L is engineered to reduce ink evaporation and prevent interaction between the system and ambient air. Its closed-loop ink system and make-up back filter evaporation recovery system effectively limit consumable loss, even in high-temperature environments.

With its Japanese-engineered design, CCS 3000L delivers exceptionally low consumable consumption in high-speed and intensive production processes and is globally recognized for this advantage.

TFT Color Touch Screen Interface

Equipped with a 5.7-inch TFT color touch screen, CCS 3000L offers simple, efficient, and user-friendly operation. The clean and intuitive interface enables easy creation of optimal codes for various product groups.

Remote control via a central computer or user interface is also supported, allowing multiple machines to be managed from a single control point. The high-contrast display ensures clear visibility even in brightly lit industrial environments.

Advanced CLOWP Software

Using the TFT color touch screen and CLOWP software, users can quickly design and print production dates, expiration dates, batch numbers, barcodes, logos, and product information.

The software allows full customization of printed data directly on the screen. Additionally, a dynamic flow system supported by multiple sensors enables real-time monitoring of maintenance and service requirements. When intervention is needed, step-by-step on-screen guidance helps operators resolve issues quickly and efficiently.

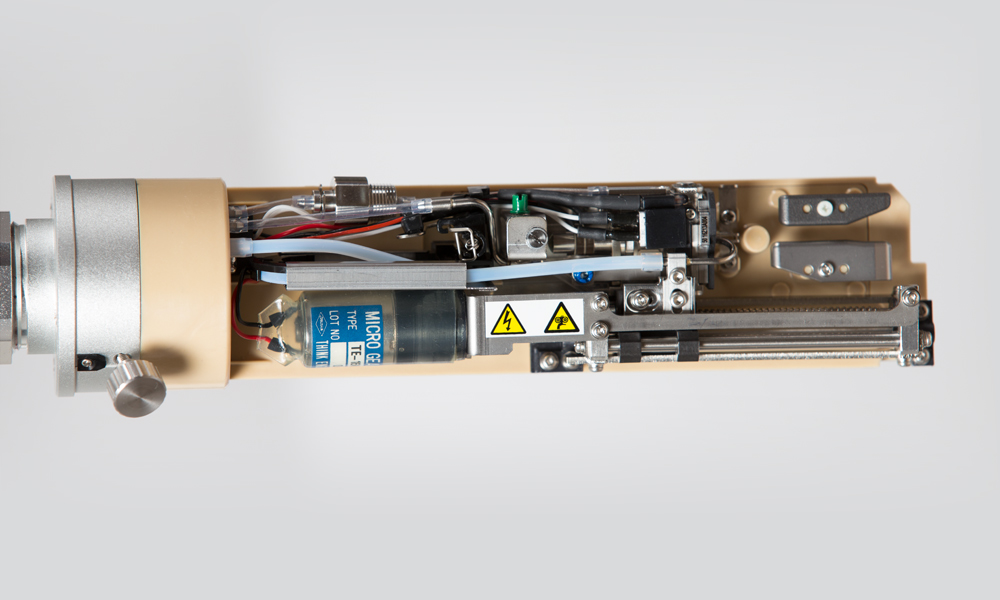

Precision Engineering and Compact Design

The compact and well-structured internal design of CCS 3000L allows operators to access and service the device with ease. All internal components are manufactured using high-quality Japanese materials and technology, ensuring long-term durability and reliability.

Automatic Operation During Long Production Downtime

To prevent issues such as ink viscosity changes and nozzle clogging, CCS 3000L automatically operates during extended production stoppages.

For facilities with intermittent production schedules, this automatic operation mode is an ideal solution. The system runs automatically for one hour per day during shutdown periods, then powers down and remains in standby mode, ensuring consistent and trouble-free printing when production resumes.

Automatic Nozzle Shut-Off System with Moving Gutter

The moving gutter system automatically aligns the nozzle and gutter when the printer is powered off, supplying air to prevent clogging and ink drying.

This innovative mechanism eliminates common inkjet issues such as nozzle blockage and ink solidification. All patent rights for this unique system are owned worldwide by KGK Co., Ltd. of Japan.